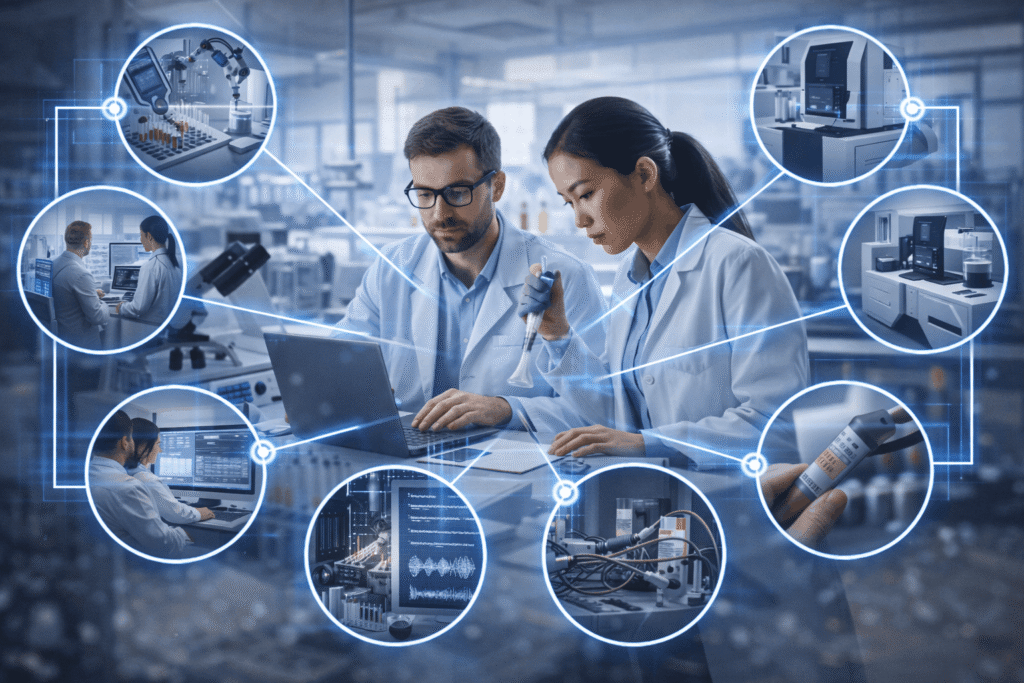

Modern laboratories generate massive volumes of data across instruments, software platforms, and teams. When these systems operate in isolation, valuable time is lost reconciling files, re-entering results, and resolving inconsistencies. This is where laboratory integration solutions are gaining attention, providing proven connectivity without the cost and delay of building systems from scratch.

In modern laboratories, system integration directly affects workflow speed, data accuracy, and operational scalability. As workloads grow more complex, connected systems become essential to maintaining control and consistency across laboratory operations.

What Is Laboratory Integration?

Laboratory integration connects instruments, software, and workflows so that data moves automatically between systems. Through effective integration with lab instruments, results flow directly from instruments to LIMS, ELN, or data platforms without manual intervention.

1. Eliminates Manual Data Entry and Data Silos

Disconnected systems force staff to re-enter data across platforms, increasing effort and risk. Integration removes these handoffs, allowing data to move seamlessly between instruments and software environments.

2. Improves Data Accuracy and Reduces Error Rates

Manual transcription introduces errors that can compromise analysis and reporting. Integrated systems capture data at the source, preserving accuracy and reducing the need for corrections or audits.

3. Accelerates End-to-End Workflow Throughput

When data flows automatically, processes move faster. Integration shortens turnaround times by eliminating delays between sample processing, analysis, and reporting, directly supporting lab workflow optimization.

4. Enhances Traceability Across the Entire Lab Process

Integrated systems create a continuous data trail from sample receipt to final output. This improves visibility, supports compliance requirements, and simplifies investigations when issues arise.

5. Enables Scalable and Flexible Lab Operations

As labs grow or adopt new technologies, integrated environments adapt more easily. New instruments or software can be added without rebuilding workflows from scratch.

6. Improves Resource Utilization and Operational Efficiency

Automation and integration reduce repetitive tasks, freeing skilled teams to focus on higher-value work. Equipment utilization improves when systems communicate and coordinate effectively.

7. Supports Advanced Automation and Future Technologies

Robotics, analytics platforms, and AI-driven tools rely on structured, connected data. Integration lays the foundation for adopting these technologies without disruption.

When Laboratory Integration Becomes a Strategic Priority

Integration becomes critical when labs experience rising throughput, increased regulatory pressure, or fragmented data environments. At this stage, integration is no longer optional; it directly impacts performance and reliability.

Key Considerations Before Starting a Laboratory Integration Project

Successful projects require clear workflow mapping, compatibility assessment, and long-term support planning. Evaluating existing systems and defining future needs early helps avoid costly redesigns later.

Integration as a Competitive Advantage

Laboratories that connect their systems gain more than efficiency; they gain control, visibility, and scalability. By leveraging reliable integration strategies and working with experienced lab automation integrators, organizations can turn data flow into a competitive advantage. Copia Scientific supports laboratories with integration-ready automation and proven solutions that align with real-world workflows.

Contact Copia Scientific to discuss how integration can strengthen your lab’s performance today and tomorrow.